Key features

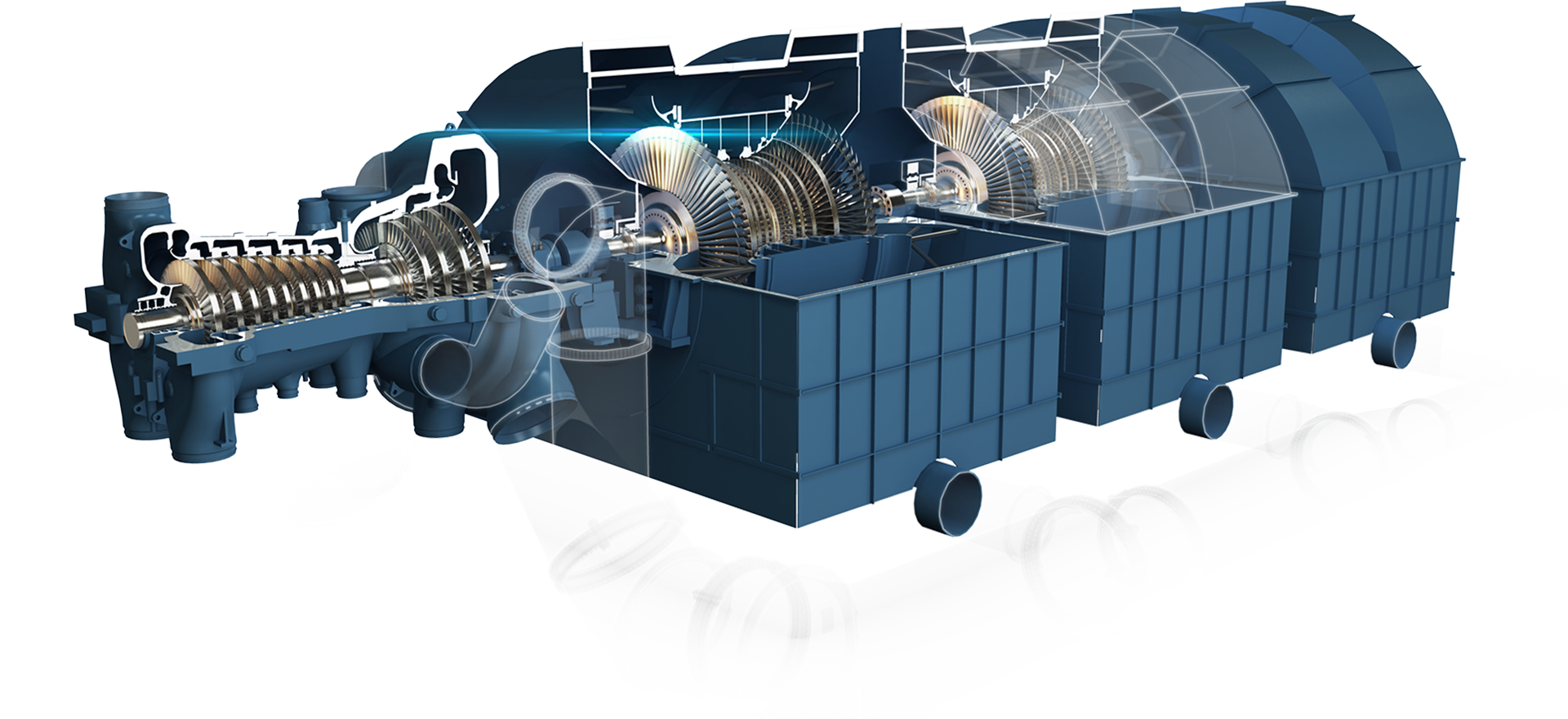

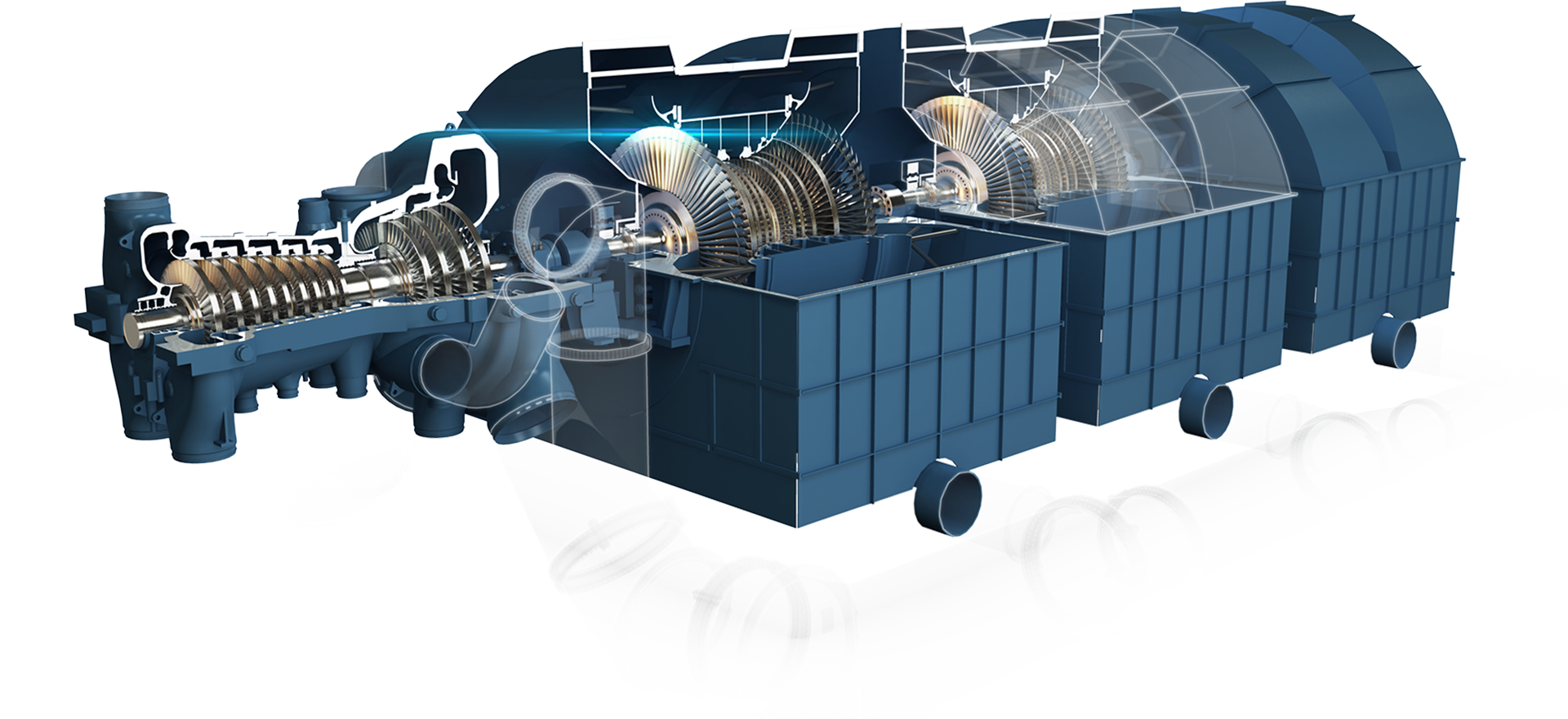

Advanced and innovative steam turbine technology

The Arabelle nuclear steam turbine suits power outputs ranging from 700 MW to 1,900 MW. Arabelle has been the largest turbine in operation worldwide for the past 20 years and has two units in China which each produce up to 1,750 MW.

Adapted for all reactor types

Fully adaptable steam path

- From 700 MW to 1,900 MW, 50 Hz or 60 Hz

- For any backpressure conditions

More power with the 1,900 MW steam turbine

Our Arabelle nuclear steam turbine features:

- A compact, powerful, efficient, and reliable turbine

- 60% of the power comes from highly efficient single flow expansion

- A unique combined HP/IP module

- Standard interface/footprint for 50 Hz and 60 Hz

Arabelle LP size configured for all site conditions

- A range of last-stage blade sizes for each frequency (50 Hz and 60 Hz)

- The largest last stage blade in operation (LSB69)

- The largest last stage blade in construction (LSB75)

- Proven blade structure with demonstrated reliability

- Two, three or four LP modules for excellent back-pressure fit

Designed for ease of maintenance

- Cross-under pipes below the foundation for reduced maintenance duration and costs

- Large lay-down areas alongside the LP modules

- Easier adjustment of LPs with independent structure

- Compact arrangement with fewer bladed rows

Additional benefits

Improved architecture for more reliability

Low pressure exhaust with independent structure

Arabelle nuclear steam turbine improves on the previous generation low pressure (LP) exhaust design with fully independent LP cylinders. By connecting the LP inner casing to an end wall rather than the LP outer casing and ultimately the turbine table, the outer casing no longer needs to act as support. This simple but powerful design innovation greatly reduces turbine load on the foundation, caused by vacuum variations or condenser forces while improving centering of moving and stationary parts.

Efficient, reliable blading

The entire family of Arabelle nuclear turbine blades features three-dimensional profiles engineered with high aerodynamic performance in mind. All rotating blades except the last stage blade (LSB) include integral shrouds to reduce loss. The resulting continuous blade structure helps create reliable and consistently good frequency control. To provide effective vibration control during service, an integral streamlined snubber interconnects the LSBs.

Specifications

Arabelle nuclear platform

Our power conversion solutions for large and very large reactors are based on our Arabelle steam turbine technology platform.

- 50 Hz

- 60 Hz

| ARABELLE 1700 | ARABELLE 1000 | |

|---|---|---|

| Typical Reactor Output | 3,500 – 4,900 MWth | 2,500 – 3,500 MWth |

| Shaft Line Rotational Speed | Half speed | Half speed |

| HP/HIP Turbine Type | 25NHIP17 | 25NHIP10 |

| Number of LP Turbines | 3 or 4 | 2 or 3 |

| Last Stage Blade Length in Inches (“) | 57, 69, 75 | 57, 69, 75 |

Specifications for EPR and CPR1000 reactors (50 Hz only)

| ARABELLE 1700 | ARABELLE 1000 | |

|---|---|---|

| Reactor Type | EPR | CPR1000 |

| Configuration | Combined HIP | Combined HIP |

| LP Turbine Type | LP75, LP69, LP57 | LP57 |

| Speed (rpm) | 1,500 | 1,500 |

| Output | 1,755 MW | 1,080 MW |

| Heaviest Lift – LP Rotor (tons) | 280 | 190 |

| Power Train Width (m) | 20 | 17 |

| Hook Height (m) | 15 | 14.5 |

| Power Train Length including Generator (m) | 70 | 56 |

Customer stories

-

Largest nuclear steam turbines ever made to boost U.K. grid

-

Powering Egypt Forward

-

Largest nuclear steam turbines ever made to boost U.K. grid

-

Powering Egypt Forward

Largest nuclear steam turbines ever made to boost U.K. grid

GE Steam Power will supply the two turbine islands for Hinkley Point C (HPC), which include the Arabelle steam turbine, generator, and other critical equipment. Already the largest steam turbine in operation in Taishan, China, the Arabelle produces 2% more power output than a traditional configuration and has a 99.96% reliability rate. HPC’s Arabelle turbines will be the largest ever built—longer than a Boeing 747 with its associated generator —and capable of producing 1,770 MW each.

3.2 GW

Output from Hinkley Point C

6 million

homes powered

9 million

tons of CO2 avoided each year

Powering Egypt Forward

GE Steam Power will deliver 4 x 1,200 MWs Arabelle steam turbines and generators for El Dabaa, Egypt’s first nuclear power plant. The power plant will deliver 4.8 GW of dependable, reliable, CO2 free energy—enough to power more than 4 million Egyptian homes.

4.8 GW

output

4 million

homes powered