The Power of Yes

Can GE provide efficient combustion for all types of industrial power plants?

YES. We have the widest custom-made boiler portfolio in the industry, more than 100 years of experience in combustion, and 30% of the global installed base of steam boiler systems. We have pioneered many technical advancements that help achieve higher efficiency, flexibility, and availability of fossil, biomass and co-firing power plants, and our high-efficiency steam boiler has a reliability rate of up to 94%.

The highest boiler efficiency in the industry

GE led the industry in developing supercritical steam generation technology, and well-positioned in today’s high efficiency ultra-supercritical (USC) PC and CFB technology. Our USC boilers contribute to cycle efficiencies of 44 to 48% lower heating value (LHV) basis, which significantly reduces both fuel and CO2 emissions for our customers.

To date, we have supplied more than 116,000 MW of supercritical pulverized coal and USC boilers worldwide and have licensed and trained other companies to install an additional 140,000 MW. The RDK8 coal power plant in Germany reached 47.5% efficiency thanks to our boiler technology.

We continue to lead the industry and invest in research and development dedicated to improving our high-efficiency steam power generation equipment, with a goal of reaching 50% efficiency.

Delivering more boiler power and operational flexibility

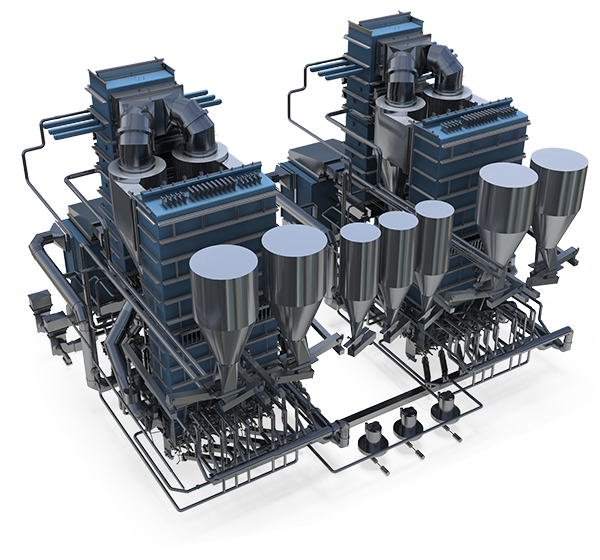

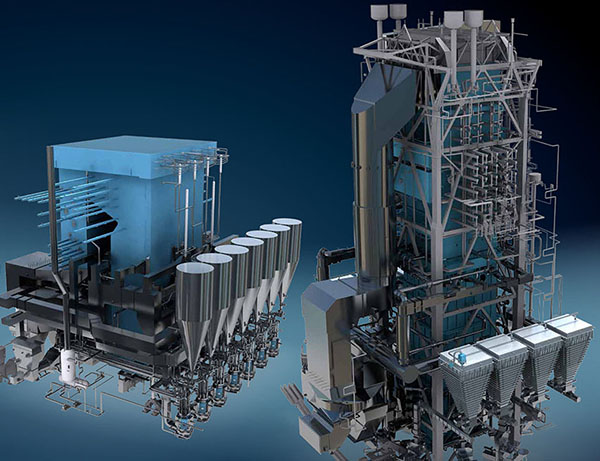

Our expertise in coal milling, firing systems, and boiler arrangements for all types of coal and other fuels helps maximize carbon burnout. This field experience, combined with our extensive laboratory expertise, is built into our design standards to ensure we offer high-performing, reliable boilers designed for industrial power plants. We also use state-of-the-art modelling and analytics to define optimal furnace arrangements. In everything we do, we ensure that our boilers are right-sized, optimized for performance, flexible, and cost effective.

Our power plant boiler portfolio addresses all fuels with PC boilers that can burn a wide range of hard coals, lignite, and oil/gas, and CFB for both conventional and difficult to burn fuels.

Our experienced-based steam boiler design enables the burning of a wide fuel range, while reducing the impact of slagging, fouling, corrosion and erosion in the furnace. This results in enhanced availability of your power plant with boiler reliability as high as 94%—and more power delivered to the grid.

If you are using imported coal, or looking at diversified coal supplies, our coal boiler system designs offer extensive fuel-firing flexibility that allows customers to safely and reliably burn a wide variety of coal.

Operational flexibility

With the increased penetration of renewable power, boilers need to be flexible and able to react quickly to changing conditions. Traditional fossil plants should be ready to operate safely through transient mode and to provide additional reserve margin for enhanced grid stability.

Our industrial steam boilers achieve these goals thanks to specific flexible operations features such as enhanced temperature control, sliding pressure capability and dynamic classifiers. Our ultra-supercritical pulverized coal boilers currently allow for ramp rates as fast as 6% per minute and down to 20% for hard coal and 35% for lignite based on BMCR. Learn more about our suite of boilers and boiler technology designed to adapt to power plants worldwide, across a variety of industries.

Did you know?

We were the first to introduce tangential firing in 1927—which creates a single rotating flame envelope (or vortex) for a uniform and consistent heat profile. This is just one of many breakthroughs we have made through constant technology upgrades that help make our boilers even more efficient and available.