Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

Thrust balance valve removal

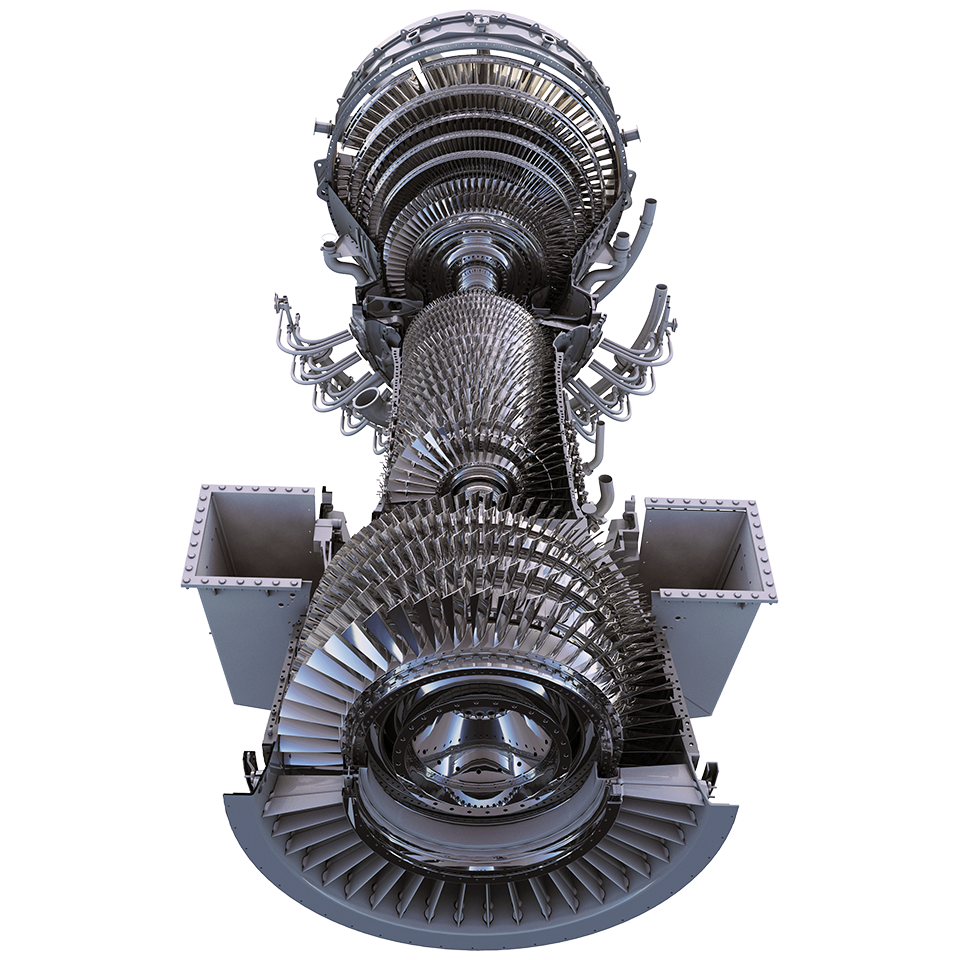

GE’s upgrade replaces the thrust balance valve (TBV) with an on-engine tube and an in-line plate orifice. Corresponding control system software modifications can lessen mechanical failures associated with the TBV.

Benefits

What can upgrading do for you?

Replacing the thrust balance valve with the new thrust balance orifice system can eliminate the maintenance and oil leaks from the TBV, and can reduce trips related to TBV software. New software is installed for monitoring thrust balance cavity pressure and annunciates an alarm, if required.

How we get you there

The orifice plate is used to passively control pressure in the piston cavity to regulate the axial position of the low-pressure rotor system and the loading of the No. 1 bearing.

- The new thrust balance design eliminates the valve and its associated hardware.

- The TBV is replaced with an on-engine tube and an in-line plate orifice, which are installed with control system software modifications.

- The new thrust balance system uses an orifice plate as a passive control system to perform the piston cavity pressure regulation.

- The tubing is mounted directly on the turbine using three transducers on the turbine rear frame struts.

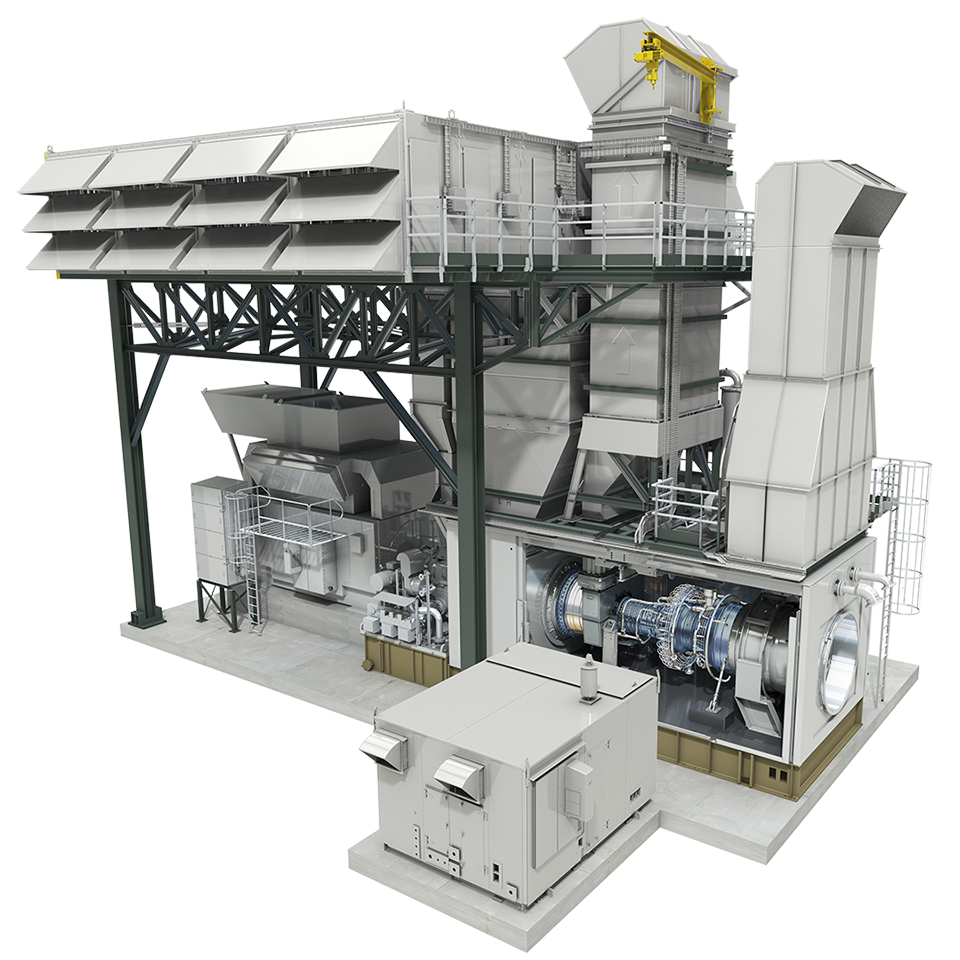

- For LM6000PC packages, at least a S4 fuel core is required. However, the S5 fuel core offers additional trip reduction logic that further improves the system.

- For LM6000PD packages, at least a S5 fuel core is required.

- For Mark VI controls, S5 core upgrade is not available on LM6000 PD units.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more