Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

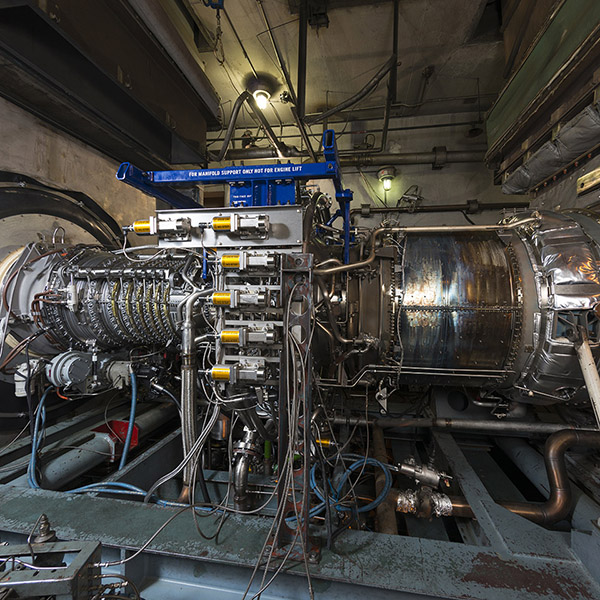

Remote VSV monitoring upgrade

A linear variable differential transducer (LVDT) is installed that allows remote monitoring of the variable stator vanes (VSV) without having to enter the package and take manual readings during engine operation.

Benefits

What can upgrading do for you?

- VSV is present to enhance efficiency over a wide range of air speeds.

- Proper monitoring of VSV position with LVDT allows the VSV to function more efficiently.

- LVDT position allows remote monitoring and accurate position of VSV to be known at all times.

- LVDT signal can be used for data or alarm processing.

How we get you there

- The VSV is part of the high-pressure compressor (HPC) assembly and thus difficult to access.

- A LVDT system can be installed allowing remote monitoring of VSV positions.

- The LVDT will be mounted on the compressor front frame (CFF) at approximately the 9 o’clock position.

- LVDT is mechanically connected to the VSV union ring by a pin and a clevis arrangement.

- Union ring movement will send a signal back to the operator through the LVDT.

Installation will include:

- LVDT transducer and hardware

- Remote signal conditioner and hardware

- Cable between signal conditioner and LVDT

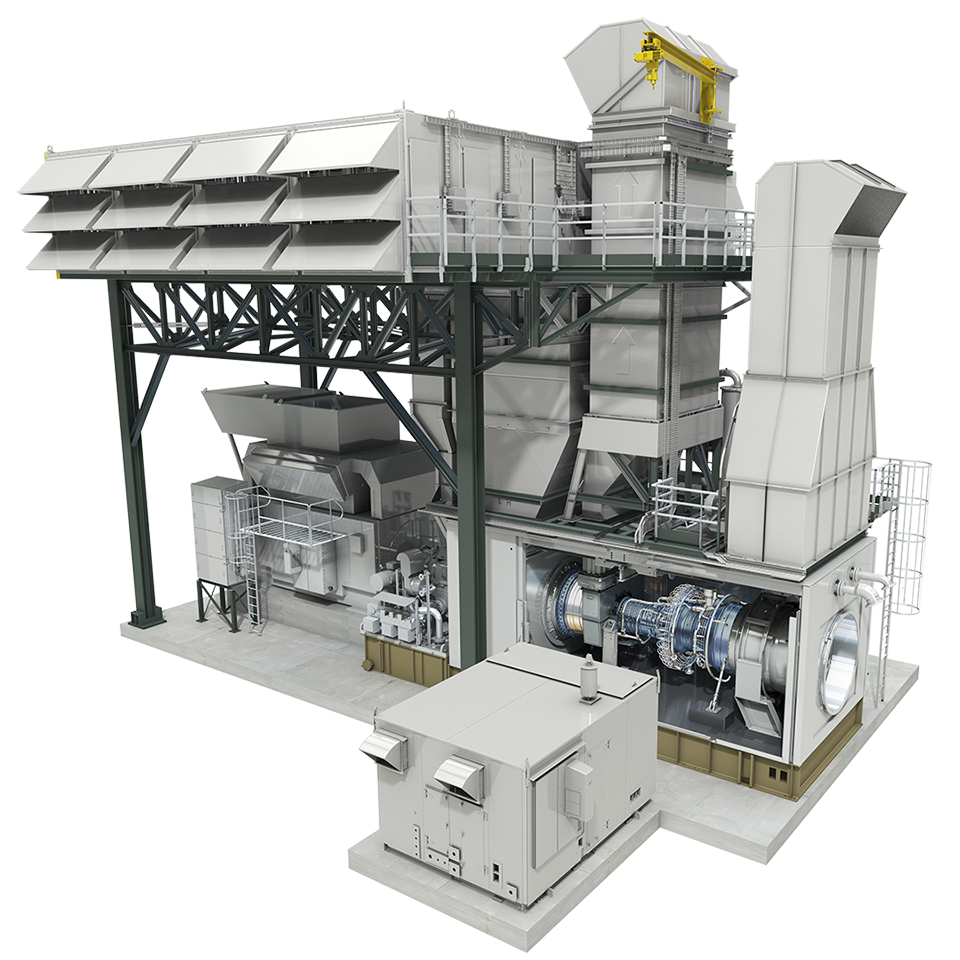

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.