Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

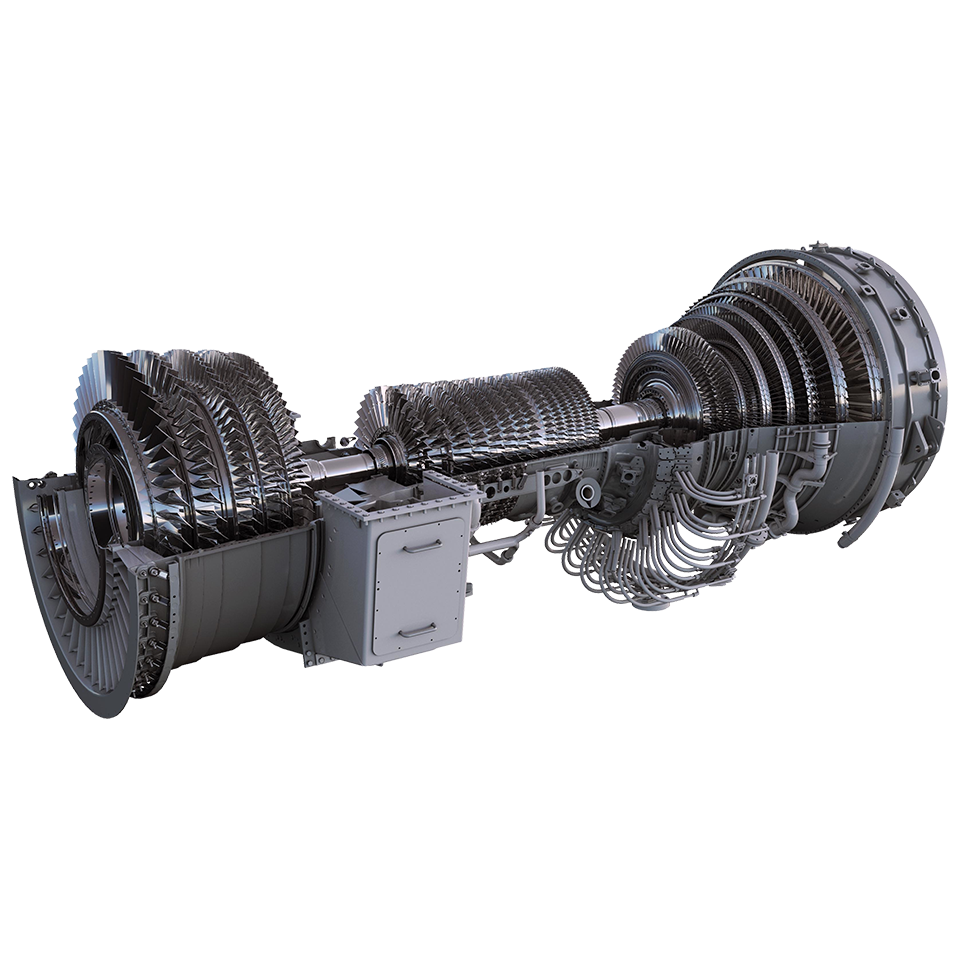

LM6000PC peak performance upgrade

The peak performance software upgrade kit enables the LM6000PC to achieve up to 5% additional output over current nominal power through peak firing.

Up to 5%

additional output

More power at the press of a button

Advantages of the LM6000 gas turbine upgrade

With the LM6000 peak performance upgrade kit, customers can see:

- Increases between 5% – 10% over current gas turbine performance have been achieved, providing viable economic benefits offsetting expected accelerated engine life

- Advanced monitoring algorithms to accurately track life impact, specifically logging: time, T48 temperature, SPRINT® flow, and NOx water flow

What can the LM6000 upgrade do for you?

- Increased SPRINT* water flow to suppress the T3 temperature to push the controls into T48 control

- Increased T48 maximum temperature to produce more power.

- Maximum NOx water ratio of 1:1

- Operable at T2 temperatures between 45°F and 85°F

This LM6000 gas turbine performance upgrade kit requires modifications

- Turbine modifications—the turbine requires that SPRINT* and VIGVs are installed, and that a borescope inspection is performed every 4,000 operating hours

- For condition-based maintenance; the service factors are current as follows:

- Fired hours factor of 2.5—every hour in peak performance is equivalent to 2.5 fired hours

- Cycle factor of 3.8—every cycle of peak performance is equivalent to 3.8 starts

- Controls modifications—upgrade to the latest fuel control software; possibly upgrade control system hardware; Tier 1 RM&D service is required; life tracking in control software and displayed on HMI

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.