Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

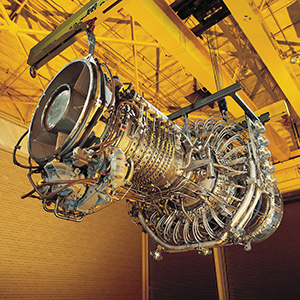

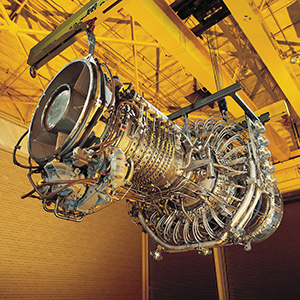

LM/TM2500 SAC to DLE

Convert your LM/TM2500 SAC gas turbine to DLE technology and reach NOx levels as low as 15 ppm for some models; eliminate water consumption for NOx control; and improve thermal efficiency.

Benefits

What can upgrading do for you?

- Triple annular configuration allows the combustor premix to operate over the entire power range, minimizing emissions at lower power.

- DLE system does not require water injection to lower NOx emissions, eliminating the possible maintenance impact of water and enhancing thermal efficiency compared to water-injected systems.

- No water or steam injection leads to increased plant operations savings.

- NOx emissions are guaranteed not to exceed 25 ppm when using natural gas fuel at full load. They can be guaranteed down to 15 ppm on the LM2500/LM2500+ models.

- CO emissions are guaranteed not to exceed 25 ppm on natural gas fuel and full load.

How we get you there

- The DLE combustion system lowers combustor flame temperature by more precisely controlling the combustion process inside the turbine.

- The lower flame temperatures reduce unburned hydrocarbon and NOx emissions.

- DLE system contains a three-manifold fuel system with new electrically actuated DLE fuel metering valves, with onboard drivers replacing electro-hydraulic actuated SAC fuel valves.

- New triple annular combustor configuration enables the combustor to burn fuel at a lower temperature over a larger cross-sectional area, achieving the same bulk gas temperature rise as the SAC system.

- Gas fuel introduced through 75 air/gas pre-mixers packaged in 30 externally removable and replaceable modules, produces a very uniformly mixed, lean fuel/air mixture.

- Optional upgrade to a new state-of-the-art control system can improve system flexibility, robustness, and more.

Services

See more related services

Looking to get more from your existing equipment? Learn more about our upgrades that will improve your turbine’s efficiency.

Don’t see what you need? Contact us

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.