Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

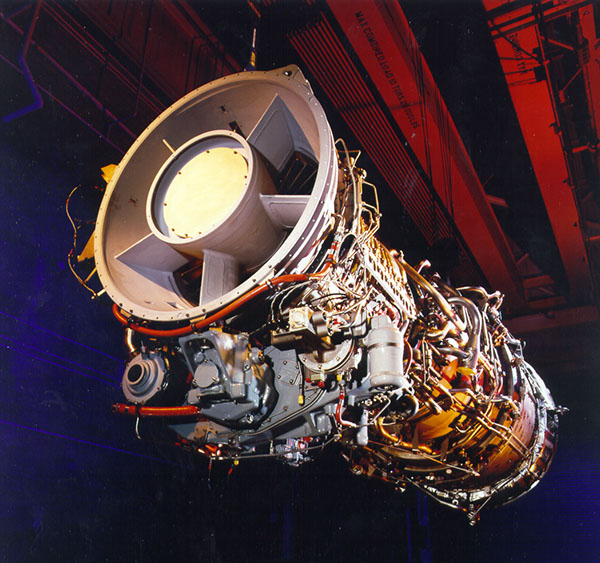

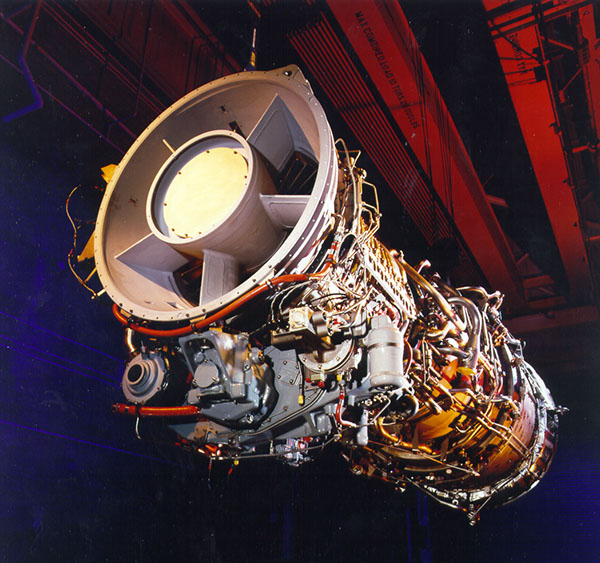

Liquid to dual-fuel LM2500

With GE’s liquid to dual-fuel upgrade, your LM2500 turbine can run on either gas or liquid fuel, with or without water injection for NOx control.

Fast facts

Applicable turbine models:

Average time to install

10 –20+ days

Inspection type

Major

Benefits

What can upgrading do for you?

The modifications consider the addition of dual-fuel manifolds with water-injection capability, including metering, shutoff valves, boost skid, and controls update as needed.

- Easily switch between fuels for increased site power-generation flexibility.

- Enhance profitability by switching to a cheaper fuel depending on market conditions.

- Increase power output using the water-injection capabilities.

- Switching to gas fuels lowers NOx emissions—and increases power outputs.

- Use GE Vernova’s Mark VI or Mark VIe, Woodward or RX3i control systems.

How we get you there

For adding gas fuel capabilities:

- A dual-fuel manifold with water injection consisting of two liquid fuel. manifolds, a gas manifold, and 30 dual-fuel nozzles.

- Gas fuel compressor (off-package if required to boost gas pressure).

- Gas fuel coalescer/dehumidifier and/or a filter/scrubber skid (off-package).

- A fuel-metering valve (on-package).

- Gas shutoff valves, check valves, and vents (on-package).

For adding liquid fuel capabilities:

- A liquid fuel forwarding skid with a 2’’ pipe customer connection with 5 psig flooded suction (off-package).

- Fuel filtered to 10 μm absolute (off-package).

- Two liquid fuel manifolds, hoses, and fuel nozzles added onto engine (on-package).

- Simplex liquid fuel boost skid (off-package).

- A duplex low-pressure filter skid (off-package).

- Fuel metering valves (on-package).

- Liquid fuel shutoff valves, check valves, and return fuel lines (on-package).

Both liquid and gas fuel conversions involve installing connections to customer fuel connections (flanged outside main base) and changing the fuel manifolds. Controls software logic and HMI changes will also be needed.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more