Delivering power around the world

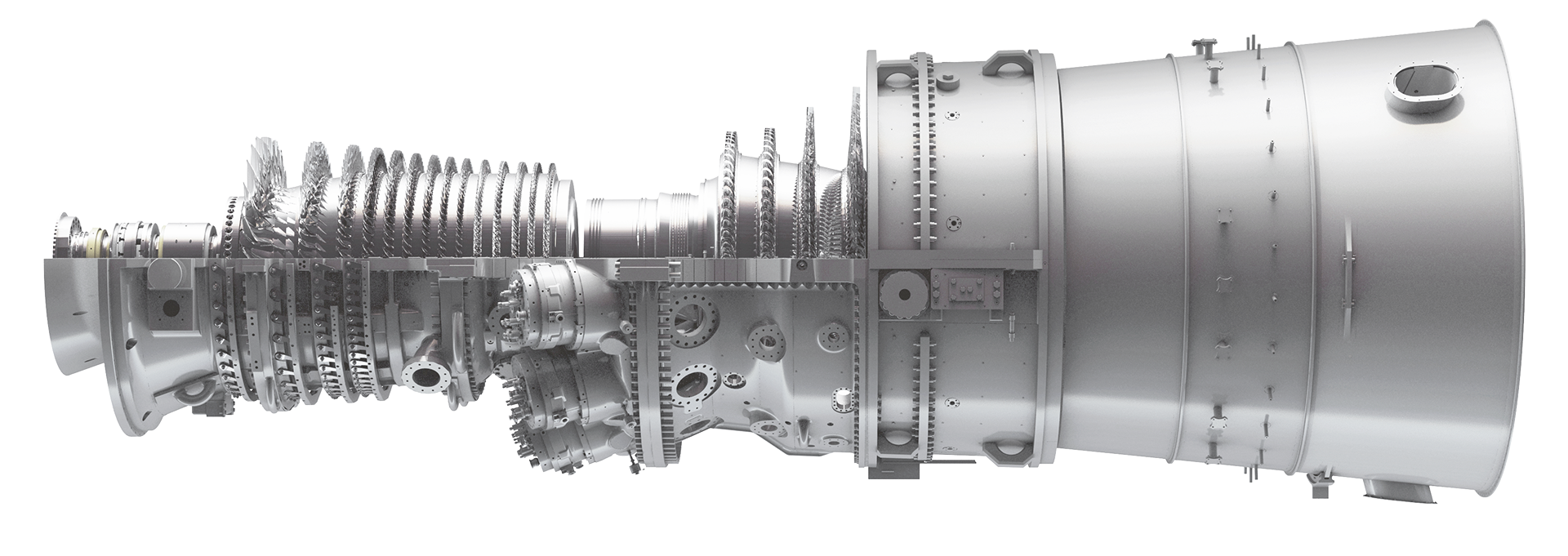

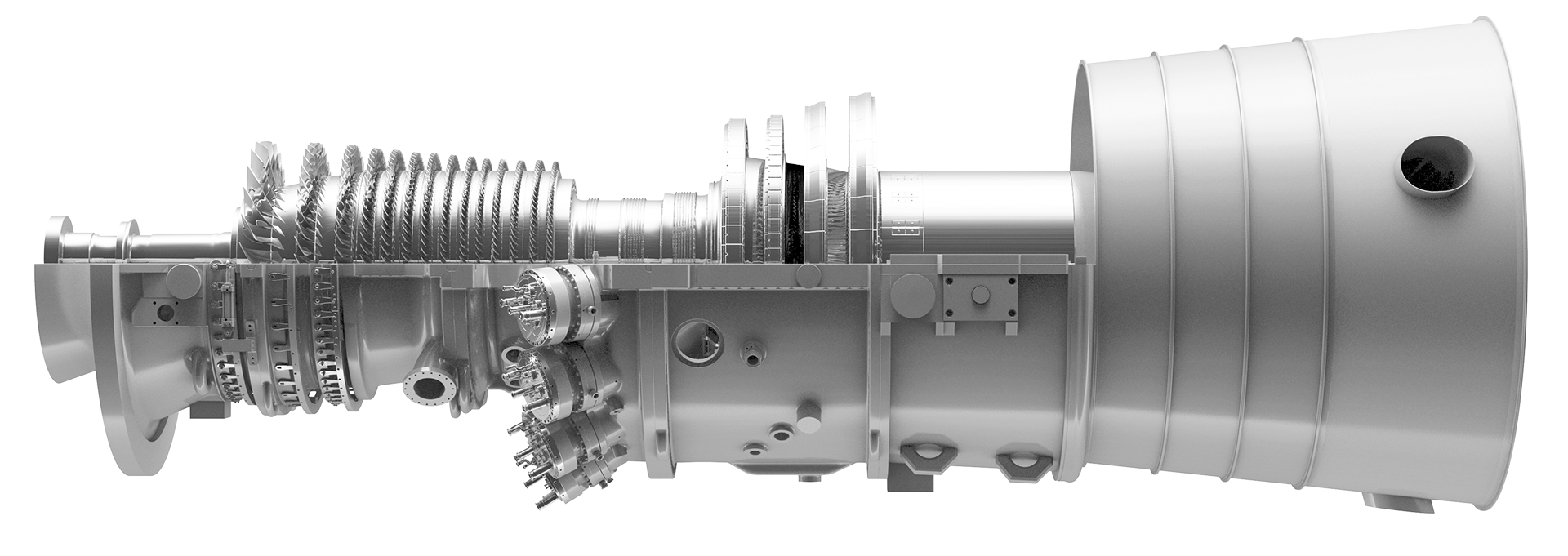

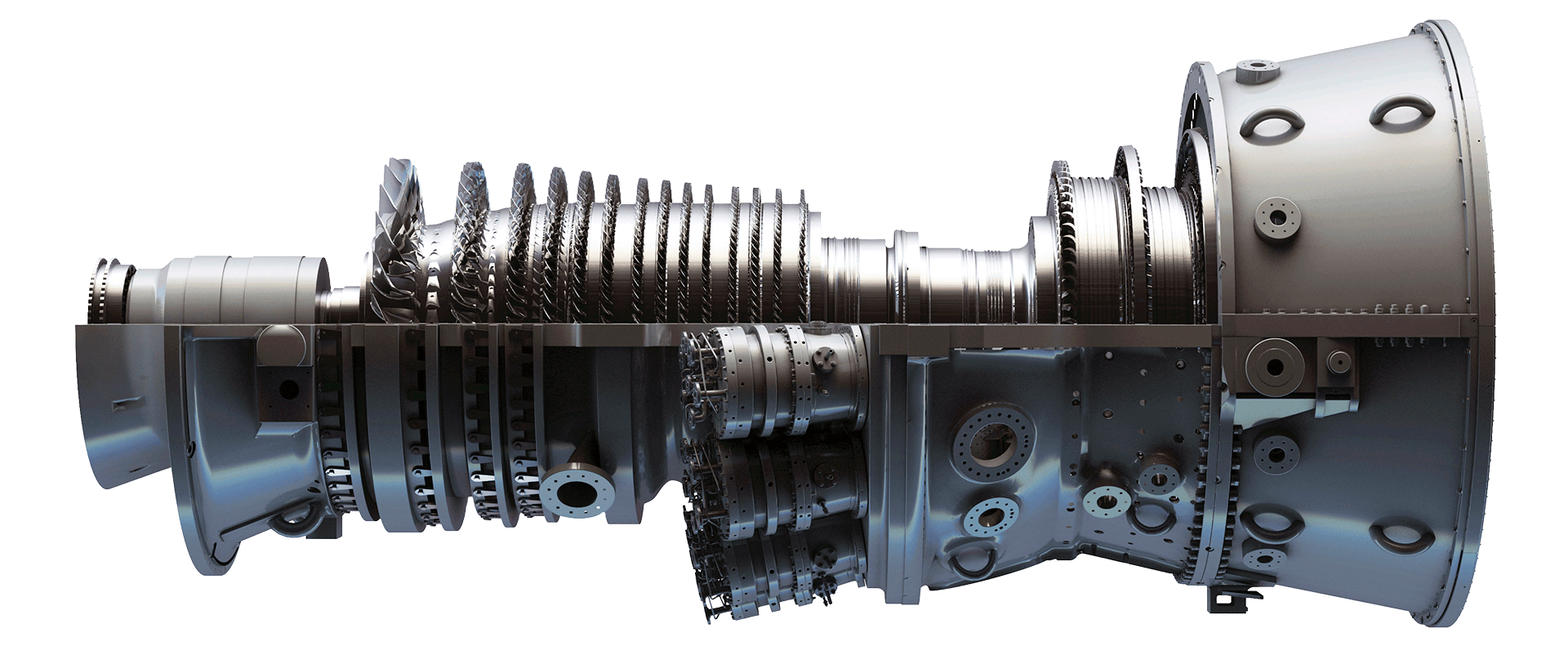

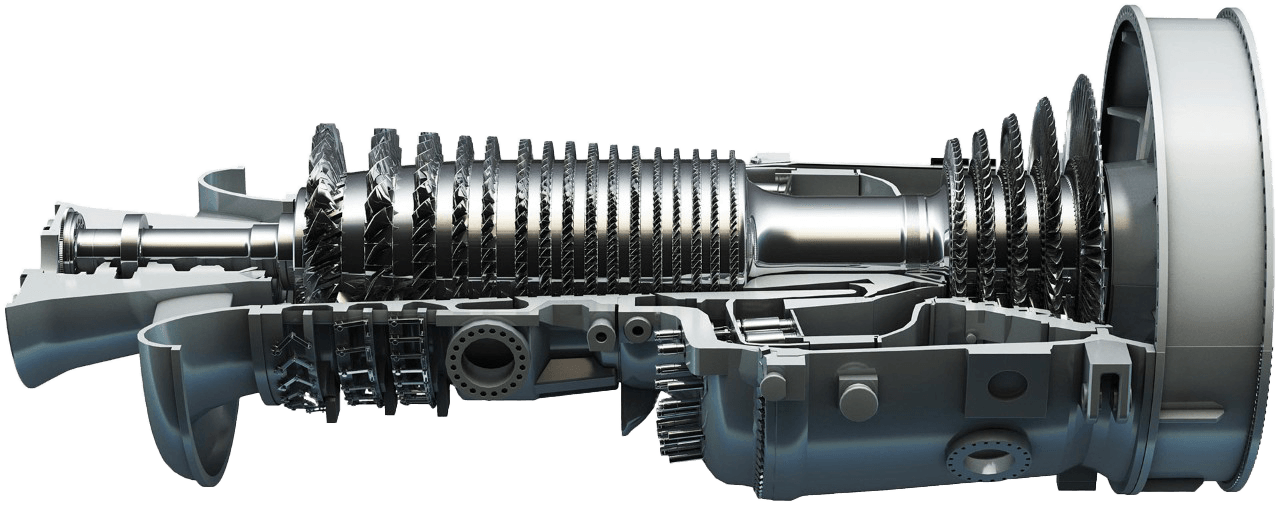

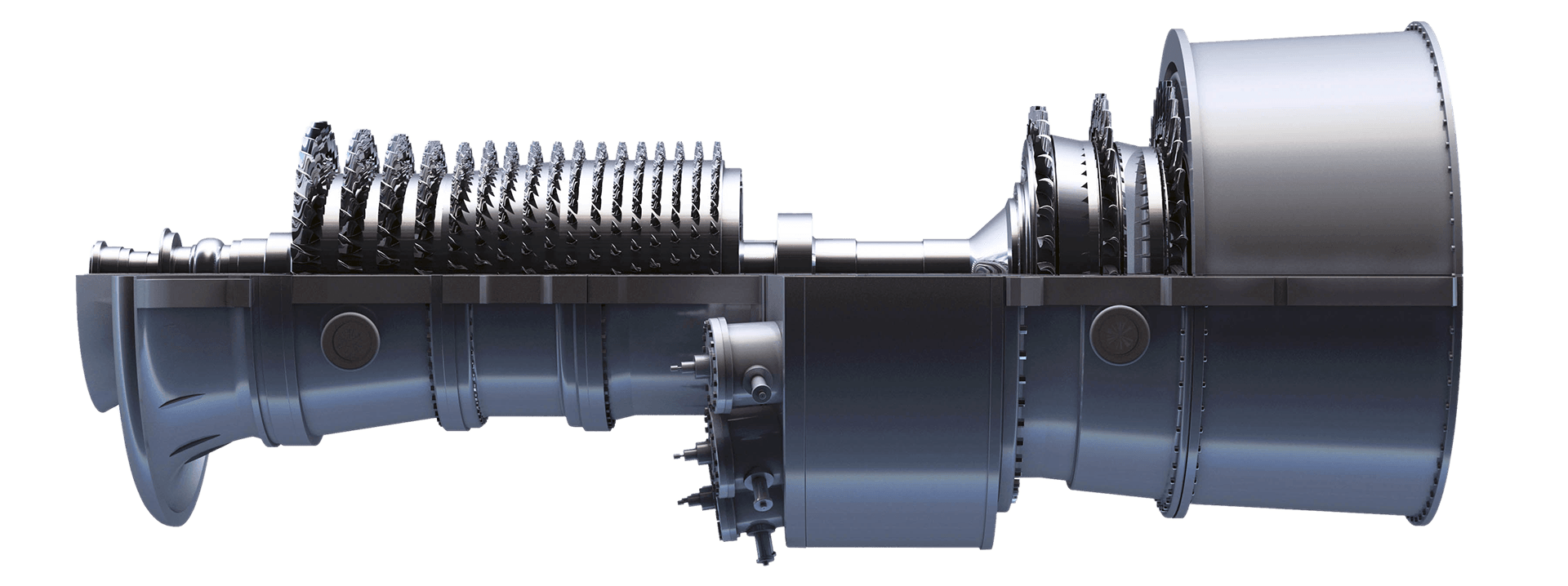

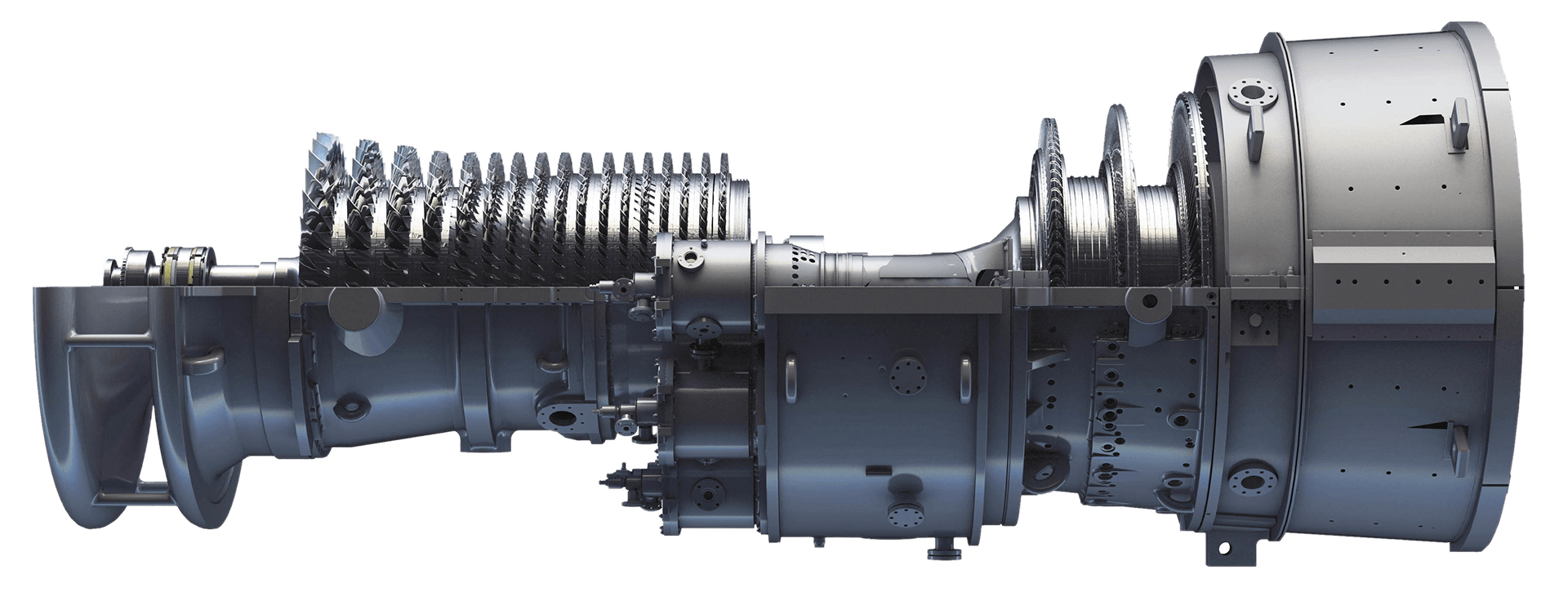

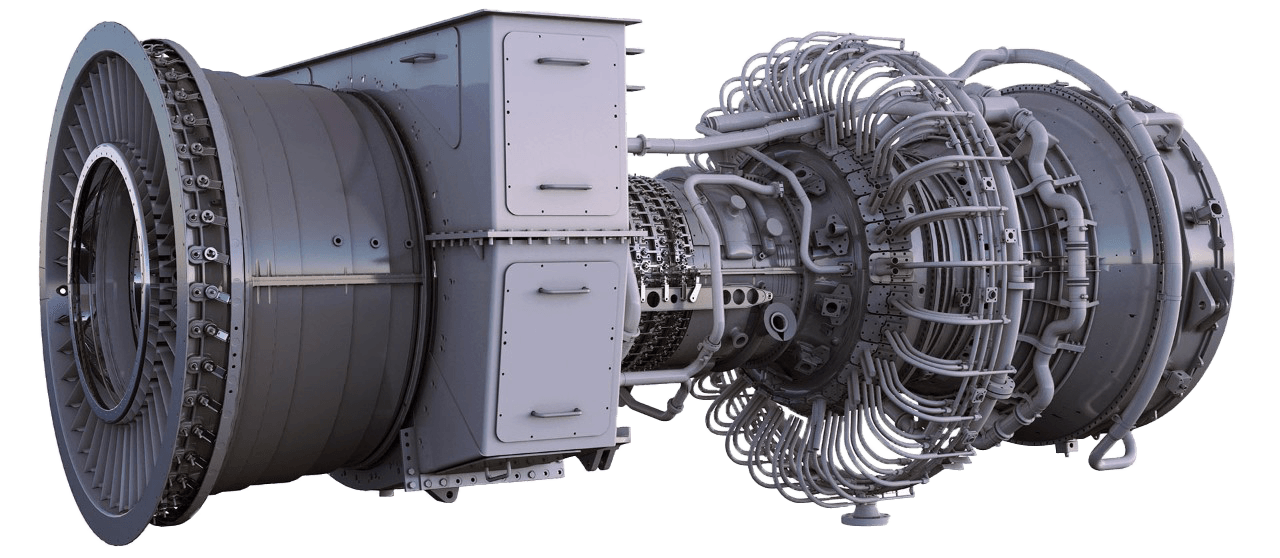

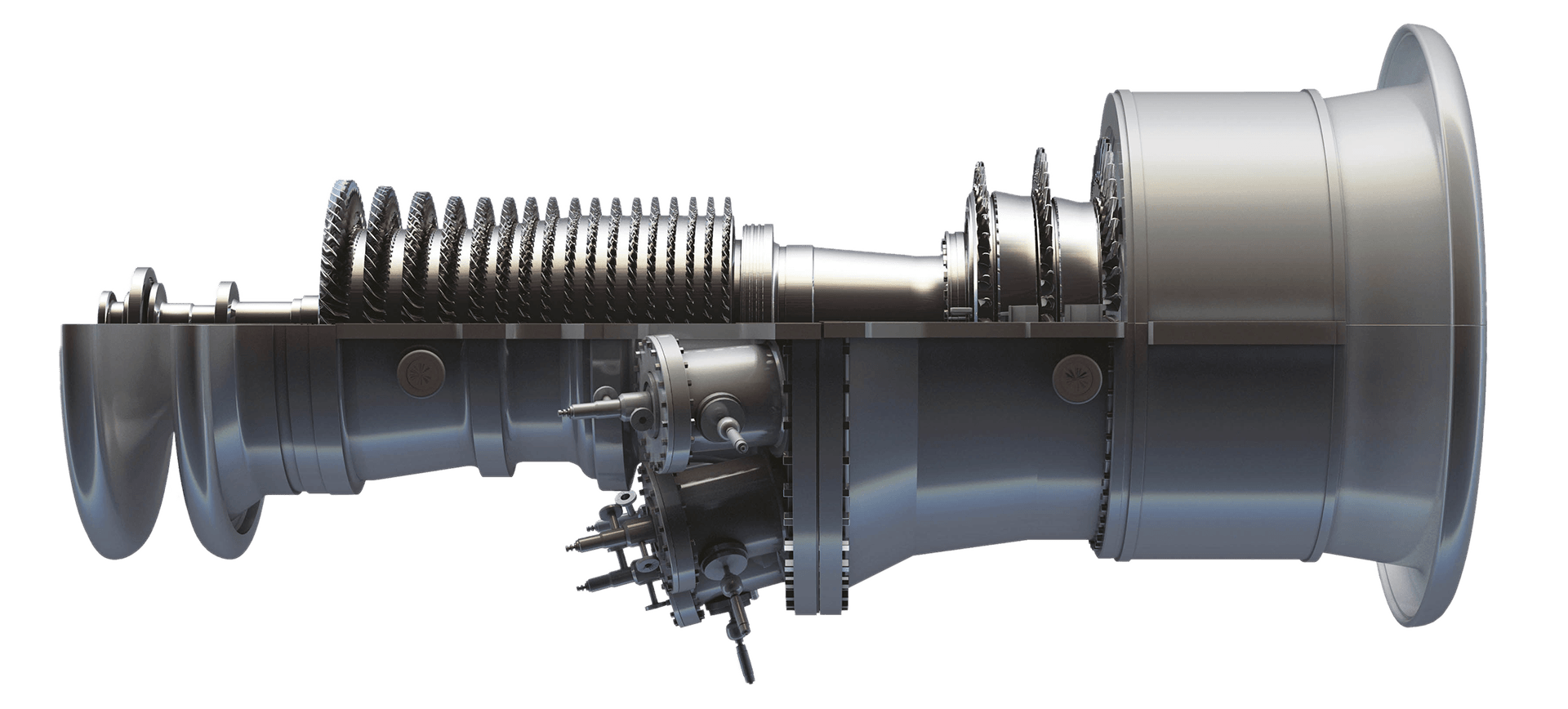

7HA gas turbine features and benefits

Whether your power plant operates at baseload or peaking profiles, you can count on GE’s 7HA gas turbine to deliver impressive performance.

Savings through efficiency

The economies of scale created by the 7HA gas turbine, combined with its 64% combined-cycle efficiency, enables the most cost-effective conversion of fuel to electricity to help power plant operators meet increasingly dynamic power demands.

Industry-leading operational flexibility

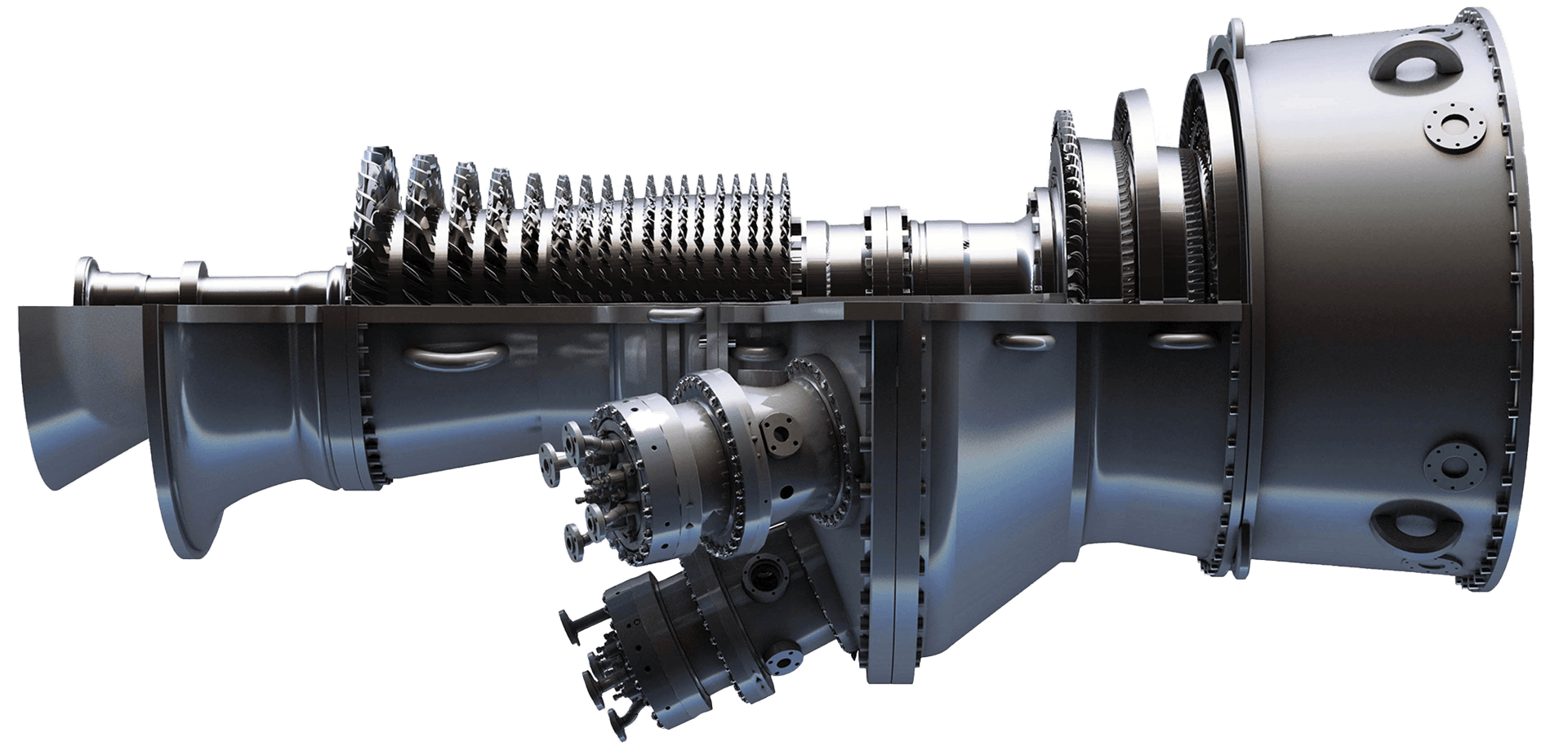

The 7HA suite of gas turbines’ flexibility enables increased dispatch and ancillary revenue, while enhanced fuel flexibility accommodates a wide range of gaseous fuels (shale gas, high ethane, H2) and liquid fuels (#2 diesel, crude oils). The 7HA gas turbine ramps up to full load in 10 minutes and features a novel configuration that supports simplified installation and maintenance.

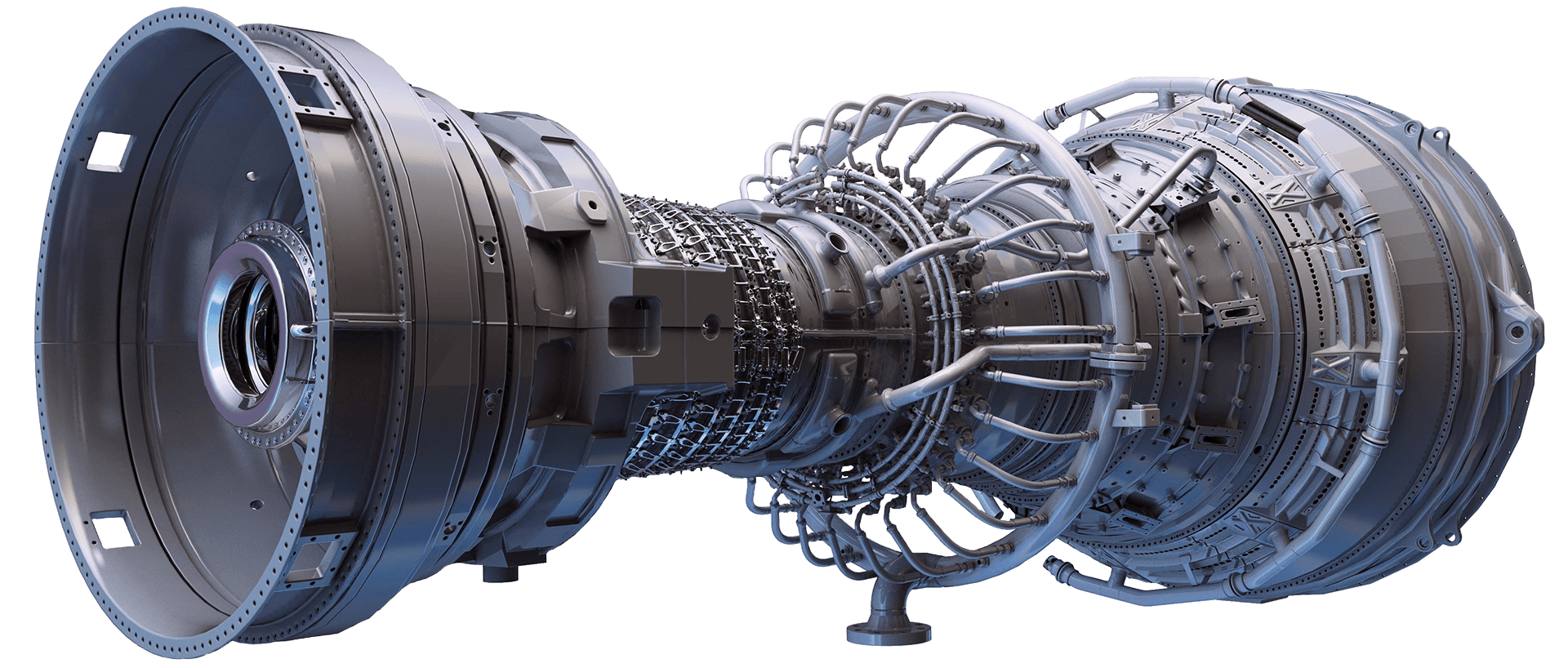

Continuously evolving combustor technology

GE’s DLN family (DLN 2/2.6/2.6+/2.6e) of combustion systems enables GE’s F-Class and H-class gas turbines to reduce NOx emissions while enabling high plant efficiency plus extending outage intervals. The DLN 2.6e maintains many of the elements of GE’s DLN 2.6+ combustion system but introduces advanced premixing to the 7HA gas turbine combustor.

Simpler configuration and modular systems

The GE 7HA gas turbine portfolio facilitates easier installation with 10,000 fewer labor hours compared to F-class turbines. Additionally, its modular configuration also helps streamline maintenance with quick-removal turbine roof, field-replaceable blades, and 100% borescope inspection coverage for all blades. Its simplified dual-fuel system uses less water, eliminates recirculation, and utilizes enhanced liquid purge for improved reliability and dependability.

Specifications

A closer look at the 7HA gas turbine

The 7HA combined cycle plant ramps up to full load in less than 30 minutes and features a novel configuration that supports simplified installation and maintenance. A 15% park mode enables customers to lower fuel burn and plant shutdown/startup costs during periods of low demand while providing a faster ramp to full load.

Specifications shown are 60 Hz

| 7HA.01 | 7HA.02 | 7HA.03 | |

|---|---|---|---|

| Net output (MW) | 290 | 384 | 430 |

| Net heat rate (Btu/kWh, LHV) | 8120 | 8009 | 7884 |

| Net heat rate (kJ/kWh, LHV) | 8567 | 8450 | 8318 |

| Net efficiency (%, LHV) | 42.0% | 42.6% | 43.3% |

| Ramp Rate (MW/minute) | 55 | 60 | 75 |

| Startup Time (RR Hot, Minutes) | 21 | 21 | 21 |

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%

NOTE: All ratings are based on ISO conditions and natural gas fuel. Actual performance will vary with project-specific conditions and fuel.

Customer stories

-

Meeting the growing needs of Florida Power & Light with the 7HA.03

-

Reliable power for district heating in Korea

-

Planning for the future

-

Meeting the growing needs of Florida Power & Light with the 7HA.03

-

Reliable power for district heating in Korea

-

Planning for the future

Meeting the growing needs of Florida Power & Light with the 7HA.03

Access to affordable, reliable and sustainable electricity is fundamental to quality of life in the modern world. To meet this growing need, Florida Power & Light (FPL) decided to install the first 7HA.03 gas turbine, the latest evolution of GE’s HA gas turbine, at its Dania Beach Clean Energy Center near Ft. Lauderdale, Florida.

$300 million

Net savings for FPL customers

24/7 power

For homes and businesses

"At FPL, we’re committed to delivering reliable energy, and as part of our longstanding program of modernizing our fleet of power-generating facilities, we are replacing an aging power plant with a new, highly efficient energy center using GE’s latest gas technology. By utilizing the most-advanced, most-efficient gas turbine in GE’s 60-hertz fleet, the 7HA.03 gas turbine, the FPL Dania Beach Clean Energy Center will allow FPL to continue delivering to customers the affordable energy they expect from us 24/7 to power their homes and businesses."

Bill Yeager

Executive vice president of engineering, construction & integrated supply chain at FPL

Reliable power for district heating in Korea

Korea’s GS Power expanded its relationship with GE with an order for a second high-efficiency 7HA.02 gas turbine and associated clutched steam turbine as well as signing a long-term services agreement. The equipment will be used for a new combined-cycle power plant in Anyang, Korea, a suburb outside Seoul. The Anyang project will replace an aging gas-fired cogeneration plant, increasing GS Power’s plant efficiency and helping to meet growing energy needs.

7HA.02 efficiency in district heating mode

Enough power for

1.87 million

Korean homes

"With GE as our partner, the benefits begin even before the power is online. The modular design configuration of GE’s 7HA technology simplifies construction and reduces installation time. Given the growth in Anyang and our need for efficient energy, that’s a real advantage."

Eung-Hwan Kim

Vice president, GS Power

Planning for the future

PSEG Fossil, a subsidiary of PSEG Power, was seeking to retire the four existing units at its 70-year-old Sewaren Generating Station in northern New Jersey. The utility set out to commission a solution that would capitalize on lower gas prices as well as reduce power plant emissions. PSEG Fossil has replaced units 1, 2, 3, and 4 of the old Sewaren plant with a new 538-MW combined-cycle power plant—Sewaren 7—featuring GE’s 7HA.02 gas turbine. In the event of a shortfall in natural gas supply, the turbine is dual-fuel capable and can operate on ultra-low sulfur distillate (ULSD) fuel oil. Compared to the old steam generators, Sewaren 7 produces the same amount of power with the 7HA.02 turbine from half the quantity of fuel and reduces emissions by about 50%.

150,000

cars from U.S. roads

500,000+

U.S. homes

"Our new Sewaren 7 plant and the 7HA.02 gas turbine will help provide the marketindustry with more reliable and cleaner power at a lower cost of generation while also supporting the local economy with employment opportunities and tax revenues."

Rich Lopriore

President of PSEG Fossil LLC

Further reading

Learn more

7HA gas turbine information

H-class technology

7HA.03 gas turbine information

Not seeing what you're looking for?

Contact us today

Videos

Learn more about the 7HA gas turbine

See how gas is complementing renewables for a sustainable and reliable energy future.

Discover GE's H-Class technology leadership

Contact us

Want to learn more about the 7HA gas turbine?

Former names of GE 7HA gas turbines: Frame 7H, 7F 7-Series, 7F-7, 7FA.06, FE60