Overview

Greenville Service Center collaborates with GE’s Repair Technology Center of Excellence (RTCoE) to map out the repair process and create the right repairs solution.

The challenge

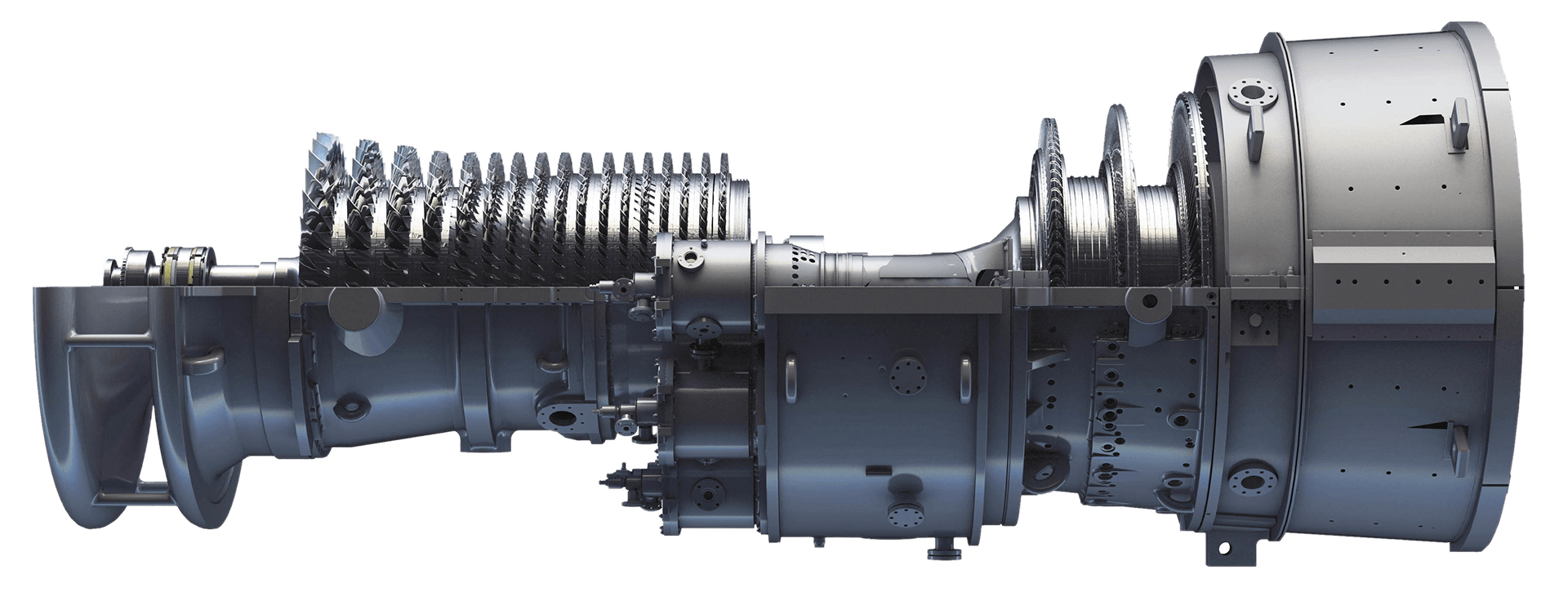

TransAlta, a power generator from Alberta, Canada, was looking to repair combustion hardware non-standard components manufactured by a third party for their GE 7EA gas turbine. TransAlta has nine gas-fired facilities and 1,578 MW of power capacity.

The solution

Components that could not be repaired were thoroughly examined to ensure the newly-manufactured replacement parts would meet customer specifications. In certain cases, GE was also able to pull GE-designed parts off the shelf that, after inspection, fit within the 3rd party combustion system assembly. This flexibility, coupled with transparent communication with TransAlta throughout the repair, helped keep budget and schedule in line with TransAlta’s expectations.

Outcomes

The GE advantage

9

Gas-fired facilities

1,578 MW

Power capacity

I was impressed with the shop… they took the time to explain all of the repairs, showed me the fit ups, demonstrated the flow tests on the fuel nozzles and answered all of my questions… I appreciated the time they took with me and the extra effort they put in repairing the parts. I look forward to coming again when our next set of parts are at the shop.

Luis Sanchez

Gas Turbine Specialist for TransAlta

To ensure that any non-standard parts designs wouldn’t negatively impact performance or durability, the Greenville Service Center collaborated with GE’s Repair Technology Center of Excellence (RTCoE) to map out the repair process and create the right repairs solution. The repair scope and technological process had to be adjusted, with all parts undergoing inspections for non-GE hardware including detailed dimensional measurements, material identification, and patent checks to remain in compliance with intellectual property and GE’s internal integrity program. A novel technological repair process – a braze repair on hard-faced surfaces – was created during this project.

This project highlights GE’s commitment to provide our customers with the full-scope repairs support they need for any parts within a GE gas turbine. Customers can count on GE’s Global Repair Solutions team to provide the right engineering capabilities with high quality standards, regardless of the original parts manufacturer.